How does Radar Level Transmitter work?

RADAR (Radio Detection and Ranging) is a device that can detect the presence of faraway objects by obtaining a reflection of electromagnetic waves emitted from the device itself.

Although invented much earlier, wide deployment of radar was done by Britain during the Second World War to detect oncoming German bombers.

Initially, radar was deployed for military purposes and for weather forecasting. Recently radar principle is used for industrial applications also.

Measurement of the level of liquids and solids is one such application.

Radar level transmitters make use of radio or electromagnetic waves of very high frequency in the Gigahertz (GHz) range.

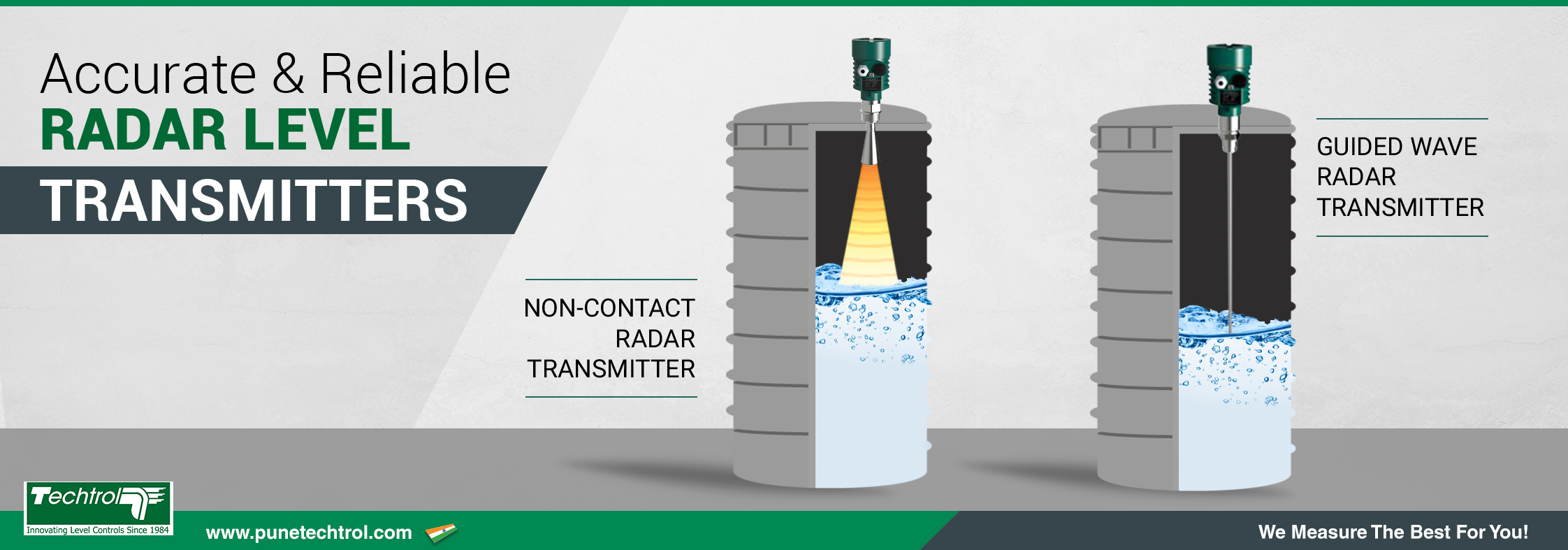

There are two types of radar level transmitter:

1) Guided wave radar transmitter

2) Non-contact type radar transmitter

1. Guided wave radar transmitter

It is based on the ‘time of flight’ principle. It consists of electronics housed in an enclosure and a waveguide i.e. probe to guide the radio wave into the process media.

Low energy electromagnetic pulses of 1 GHz from the electronics are transmitted along with the probe which travels down along the probe at the speed of light into the process media and their partial energy is reflected back to the sensor circuitry.

The intensity of reflection depends on the dielectric constant value of the media. The electronics measures the time delay between transmitted and reflected signal and calculate the distance of the surface of process media using formula –

Distance = (Speed of light x time delay) / 2, Level = (Tank height – Distance)

The Radar Level Transmitter is programmed with tank height and the corresponding level is calculated by the microprocessor.

It is also used for liquid-liquid interface level measurement only when upper layer media is of low dielectric and the difference between two dielectric constants is >10.

Residual electromagnetic pulses after the first reflection continue to travel down the probe through the low dielectric media and again reflected back. The second reflected signal determines the interface level.

Advantages:

- Provides accurate & reliable level measurement of liquids, slurries, pastes, liquid interface & solids.

- Suitable for low dielectric constant media.

- Unaffected by liquid turbulence, change in density, dielectric constant, conductivity, foam, dust, temperature & pressure

- Minimal maintenance as no moving parts

2. Non-contact radar transmitter

It uses a high-frequency microwave signal of 26 GHz which is transmitted via an antenna towards the product surface. Its frequency increases linearly during the measurement.

The signal is reflected back to the antenna from the surface of process media and received at the time-delayed frequency.

The difference is calculated from actual transmitting frequency and received frequency which is directly proportional to distance to the liquid surface from antenna.

The frequency of non- contact radar level transmitter affects on the performance of the level transmitter. Lower frequency increases the beam width and reduces the sensitivity due to vapor, foam, and deposition on the antenna.

With higher frequency, the beam width is narrowed which minimizes the influence of nozzle, wall and tank internals.

Advantages –

- Suitable for liquids, solids & granules

- Reliable performance with high accuracy up to 1mm

- Choice of antennas- sealed rod, horn, drop or parabolic to suit the application

- Unaffected by liquid turbulence, change in density, dielectric constant, conductivity, foam, dust, temperature & pressure