Support

FAQ - DISPLACER SWITCH(DS)

1.For which applications displacer switch is recommended?

For medium or large tanks having limited free space at its top

2.Whether displacer switch is used for slurry?

Yes, It is suitable for free flowing liquids - clear, clean, corrosive, non-corrosive liquids & slurry with

Non-sticky, minor suspended particles.

3.In which materials, displacer switch is available?

It is available in SS304, SS316, SS316L, PP, PTFE and PVDF material to suit corrosive and non-corrosive services.

4.Whether the switch is used for turbulent liquid?

Yes. For severe turbulence in liquid, it is recommended to use perforated stillwell with switch.

5.Whether the switch is used for hazardous area applications?

Yes. Displacer switch with flameproof enclosure Exd Gr. IIC T6 or ATEX Exd Gr. IIC T6 are available for hazardous area applications.

6.Whether CCOE/ PESO certified enclosures are available?

Yes. CCOE/ PESO certified flameproof enclosures are available for hazardous locations.

7.How many set points are available with DS?

Max 3 set points (adjustable at site)

8.Whether switching contacts can be configured with PLC/ DCS?

Yes. As potential free contacts

9.What is the switch type and its contact rating?

Switch Type = Micro switch x 2 SPDT contacts

Contact Rating = 5A @ 250 VAC

10.Whether hermetically sealed switch is available with displacer switch?

The micro switches are hermetically sealed in casing. They are available with A, B, C, D & F configurations.

11.Whether the switch needs to be set at site?

Yes. While shipping, displacers are positioned at top and its wire rope is wound on displacer. During installation, unwind the rope, loosen the fixing screws on displacer and relocate the displacer at required position of operating point on the wire rope. Retighten the fixing screw.

12.How many configurations (types) of displacer switches are available?

There are six configurations by using standard displacer and split displacer. Shows how wire rope is wound on displacer while shipment

| Config | Switch Carriage x Displacers | Differential | Applications |

|---|---|---|---|

| A | 1 Sw. Carriage x 1 Std. Displacer | Narrow | Single point switching to initiate Alarm or Pump ON or Pump OFF action |

| B | 2 Sw. Carriage x 2 Split Displacer | Wide | 1 no. Pump Control |

| C | 2 Sw. Carriage x 2 Std. Displacer | Narrow | Two point switching to initiate ON or OFF action of auxiliary devices |

| D | 2 Sw. Carriage x 1 Std. + 2 Split Displacer | Narrow + Wide | Single point switching to initiate Alarm with single displacer switch and pump control using 2nd switch with 2 split displacer. |

| E | 3 Sw. Carriage x 3 Std. Displacer | Narrow | Three point switching to initiate ON or OFF action of auxiliary devices |

| F | 2 Sw. Carriage x 4 Split Displacer | Wide | 2nos. Pump Control |

13.What is switching differential?

It is difference of level between points of actuation and di-actuation of switch.

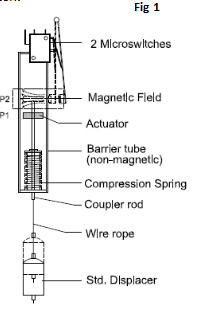

14.How does displacer switch work?

Displacer is suspended on wire rope and connected to a coupler rod, carrying an actuator, which moves within seal pipe through a spring. A switch carriage with magnetic system is fitted on seal pipe inside the enclosure Here as the liquid level rises, displacer get submerged in the liquid and experience an upward buoyant force. Hence actuator moves upward and comes in magnetic field to actuate micro switch lever and change over contacts.

During falling of liquid level, displacer comes out of liquid and gain weight and actuator comes out of magnetic field and micro switch lever is released and de-actuate. Refer fig 1

15.How does narrow differential switches and wide differential switches work?

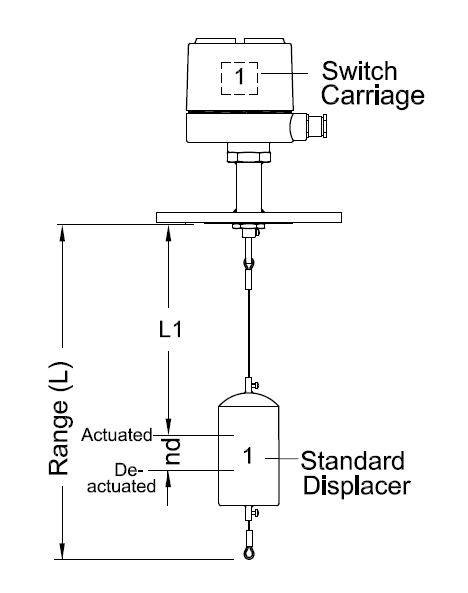

Narrow Differential Displacer Switch – (Fig 2)

In this standard displacer is used against each switch carriage.

Let us see working of displacer switch with Config. A: 1 switch carriage x 1 std. displacer.

During Rising Level: Switch actuates at L1 & remains actuated during further level rise.

Falling Level: Switch de-actuates at (L1+nd) & remains de-actuated during further level fall.

(nd = narrow differential)

Here the difference between the switch actuation point and de-actuation point (differential) is narrow and fixed, around 40±5 mm depending on configuration. Refer catalog for details, Similarly, in config. C, two std. displacers are provided with two switch carriage and in config. E, three displacers with three switch carriage. Both the model comes with narrow differential.

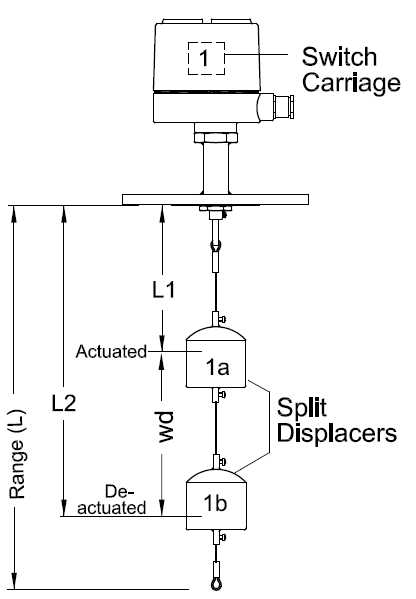

Wide Differential Displacer Switch – (Fig 3)

Here two split displacers are used against one switch carriage. The weight and volume of two split displacer is equal to single standard displacer.

Rising Level: Switch actuates at L1 & remains actuated during further level rise.

Falling Level: Switch de-actuates at L2 & remains de-actuated during further level fall.

Here the difference between the switch actuation points and de-actuation point (differential) is wide and adjustable over the range by relocating the displacers to adjust switching points L1 & L2 at required location

16.Which models come with narrow differential?

Switch models with standard displacers comes with narrow differential. Refer catalog for detail.Switch models with standard displacers comes with narrow differential. Refer catalog for detail.

17.Whether narrow differential can be adjusted?

No. It is fixed.

18.For what applications, narrow and wide differential switches (DS) are used?

Switches with Narrow Differential - to initiate alarm or pump on or pump off action

Switches with Narrow Differential – for pump control

19.Which models come with wide differential?

Switch models with split displacers comes with wide differential. It is adjustable and can be modified at site.

20.Whether wide differential is adjustable?

Yes. It is adjustable within the range.

21.What is minimum liquid specific gravity for which the switch works?

Switch is suitable for sp. gr. of 0.8. However for lower sp. gr < 0.8 to 0.5, switch is provided with specially designed displacer.

22.What is the maximum operating temp & pressure limits

|

MOC |

Max. Temp (°C) |

Max. Pressure (kg/cm2) |

|

PP |

70 |

Vacuum to 1 |

|

PVDF/PTFE |

100 |

Vacuum to 1 |

|

SS |

200; High temp 300 with radiating fins |

Vacuum to 10; High pressure upto 100 kg/cm2 on demand |

23.What information is required to get quotation at earliest?

• Tank Details – tank height/ depth, Nozzle length & its ID.

• Liquid, its nature (corrosive, suspended particles, fuming, viscous) and its specific gravity.

• Operating Conditions – max temp & pressure, any agitation in tank or turbulence in liquid

• Area classification- Safe or hazardous

• Accessories (Stillwell or External Chamber) required if any

24.What are the advantages of displacer switch over float switch?

• Longer range upto 15mtrs

• Easy to handle& install

• Set points are easily adjustable at site.

• Unaffected by surge or turbulence in liquid.

• Inbuilt pump control function with wide differential displacer switches

• High pressure upto 100 kg/cm2& high temperature upto 300?C

25.What approvals & certifications are available for displacer switch?

• CE certification

• CCOE approved Ex-proof enclosures Exd Gr. IIB or IIC T6 for hazardous area applications

• ATEX approval Ex d Gr. IIC T6 for hazardous area applications

• IBR approval

26.Which factory tests are provided for the switch?

• Hydro Test, Performance Test, Insulation and HV

All Rights Reserved © 2021 PUNE TECHTROL PRIVATE LIMITED

Engineered by THE IMPALS