Support

FAQ - FLOAT & DIAL GAUGE(FDG)

1.For what applications FDG is most suitable?

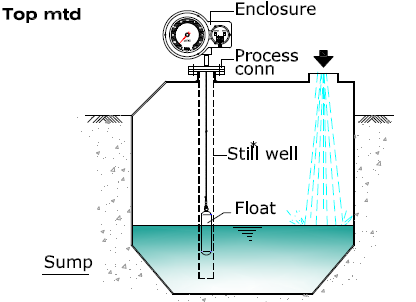

FDG is most suitable for sumps (underground tank) or partially underground tanks or the tanks having limited headroom upto 10 mtrs depth and ground level tanks.

2.Can FDG be used for any liquids?

Yes, It is suitable for free flowing liquids - clear, clean, corrosive, non-corrosive liquids & slurry with non-sticky, minor suspended particles

Examples - Water, Dosing liquids (Lime, Alum, Poly etc.) or Effluent

Diesel, LDO, Oil, Solvents (Toluene, IPA, Methanol etc),

Acids & Alkalis (NaCl, Sulphuric acid etc)

3.Whether FDG is suitable for slurry or sludge?

Yes, FDG is suitable for free flowing slurry, containing moderate non-sticky suspended particles, however it is not suitable for thick sludge.

4.Whether FDG is suitable for turbulent liquids or tank having agitator?

Yes, using perforated Stillwell.

5.What information is required to get quotation at earliest?

• Tank Details – tank height/ depth, Nozzle length & its ID.

• Liquid, its nature (corrosive, suspended particles, fuming, viscous) and its Specific Gravity.

• Operating Conditions – max temp & pressure, any agitation in tank or chances of turbulence in liquid?

• Area classification? Safe or hazardous

• Whether switching o/p or 4-20 mA transmitting o/p is required?

6.What are benefits/ advantages of FDG?

• Most suitable for underground tanks

• It is compact, easy to handle and install on tank top having depth upto 10 mtrs.

• Can be easily retrofitted on existing tanks

• Choice of indication – Analog with bright red color pointer moving on a dial Digital on bright red color seven segment LED display. Level indication can be easily viewed from a distance

• Factory calibrated, ready to install. If required, easy to calibrate on field.

• Local indication alogwith option of two alarm switches and 4-20mA transmitter o/p

• Weatherproof IP66 enclosure with analog indication for outdoor installations and flameproof enclosure Ex d Gr. IIB with digital indication for hazardous area applications.

7.What is the operating temperature?

Operating Temperature: - 10 to 100 ?C

8.Whether the gauge can be used for pressurized tank?

No..

It can be used for tanks which are open to atmosphere or closed tank under atmospheric pressure.

9.How FDG works?

The gauge consists of float suspended on wire rope. The other end is wound on a pulley carrying constant torque spring housed in an enclosure. The constant torque spring maintain the rope under tension. As liquid level changes wire gets wound /release from the pulley and pointer moves on the scale through gear mechanism. In case of digital indication, gear motion induces change in variable voltage signal which is converted in 4-20 mA output and provides digital indication.

10.Does the gauge require power supply?

FDG Analog : Does not require power supply.

However for FDG with transmitter require 24 VDC supply.

FDG Digital : Works on 24 VDC power supply.

11.What is the output of FDG?

FDG Analog : Indication of level on dial.

: Option of max 2 switch o/p and or 4-20 mA transmitter o/p

FDG Digital : Indication of level on seven segment LED display.

12.What is the accuracy of FDG?

• Accuracy of analog indicator is ±50 mm

• Accuracy of digital indicator is ±2% FSD

13.Whether the gauge is suitable for hazardous area applications?

Yes.

FDG (digital indication) with ex-proof enclosure Exd Gr. IIC T6 is used for hazardous area applications

14.Whether PESO certified ex-proof enclosure is available with FDG?

Yes, available with digital indication.

15.How FDG is mounted on the tank?

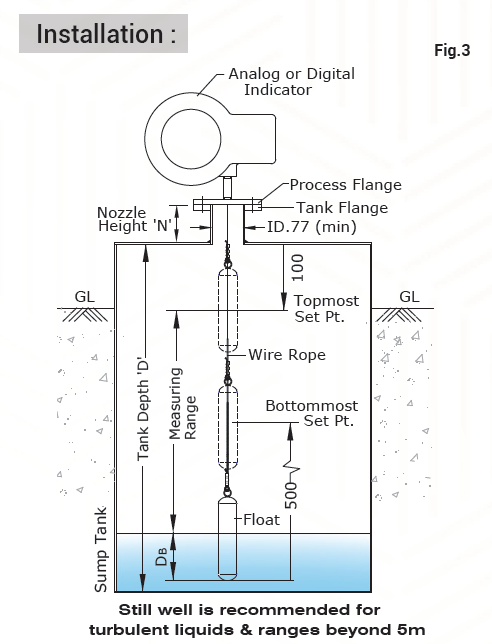

The gauge is installed on tank nozzle from top. Tank flange & gauge flanges are bolted together with gasket in between. In case of stillwell installation, install stillwell first on tank nozzle and then mount FDG on it. Then bolt all tank flange, stillwell flange and gauge flange together with gaskets in between.

16.Whether the measuring range is adjustable?

No.

17.Whether zero pointer can be set on scale?

Yes, Zero pointer of the gauge can be easily adjusted by removing the dial cover and loosening the point knob.

18.Whether the switch set points of FDG are adjustable on site?

Switch set points are set at factory as per required set points mentioned in PO. However it can be set at site, refer instruction manual or contact service department.

19.Whether transmitter o/p (4-20 mA) is required to be calibrated at site?

No.

Transmitter is calibrated in factory for required measuring range. However fine tuning of calibration can be done on site, refer instruction manual or contact service department.

20.What is contact rating of the switch o/p and whether it can be connected to PLC?

Contact rating of switch is 5@ 250 VAC. These potential free switch contacts can be connected to PLC.

21.Whether transmitter o/p can be connected to PLC?

4-20mA output of analog indicator can be connected to PLC 4-20 mA output of digital indicator require signal isolator, as it is floating o/p and there may be chances of no common ground between o/p of FDG & input of PLC. Hence Isolator is recommended.

22.Whether the FDG can be used for floating roof tanks?

Yes, we can provide. Please enquire sales team

23.Whether volumetric scale can be given in unit other than specified in catalog?

For FDG Analog – Please enquire sales team.

For FDG Digital - Can be set for %, mm, cm, mtrs and volumetric unit for linear tank.

24.Whether switches are provided with ex-proof enclosure?

No. For switching o/p, you can use controller (TLIC or TUIC) along with FDG and its relay o/p can be used for switch action and its advantage is that these relay switching points are easily settable.

25.What is minimum and maximum switching set point that can be achieved in FDG analog?

Adjacent figure is from catalog. It shows -

Top most set point can be given at 100 mm from tank top. (If nozzle is there, add its length in it)

Bottom most set point can be given at 500 mm from bottom of the tank

All Rights Reserved © 2021 PUNE TECHTROL PRIVATE LIMITED

Engineered by THE IMPALS