Support

FAQ - FLOAT GUIDED TRANSMITTER(FGT)

1.For what purpose float guided level transmitter is used?

It is used for continuous level measurement of liquids in an open or closed tanks.

2.Whether the transmitter is suitable for slurry and viscous liquids?

Yes. It is suitable for free flowing liquids - clear, clean, corrosive, non-corrosive liquids and free flowing slurry, viscous / sticky liquids with minor suspended particles.

3.Does the transmitter is suitable for liquid – liquid interface?

Yes. The difference between specific gravity of upper and lower liquid should be greater than 0.2.

4.Does the float get stuck in case of slurry and viscous liquids?

No. Due to self-cleaning construction of the float, it is suitable for free flowing slurry and viscous liquids.

5.In which material float guided transmitter is available?

It is available in SS304/316/316L, PP and PVDF material.

6.Whether the transmitter can be used for turbulent liquids?

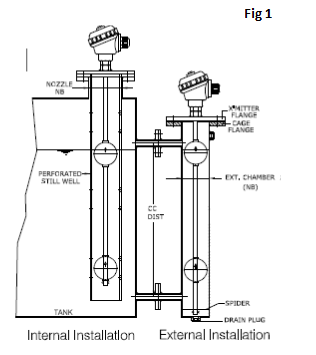

It works well for turbulent liquids. However, for severe turbulence in liquid, it is recommended to use perforated stillwell with transmitter.

7.How transmitter is installed on tanks having limited space inside?

It is recommended to mount the transmitter using external chamber.

8.Whether the transmitter can be used for hazardous area applications?

Yes. The transmitter is available with flameproof enclosure Exd. Gr. IIC, T6 or ATEX Exd Gr. IIC T6 or with intrinsic safety option.

9.Whether CCOE/ PESO certified enclosures are available?

Yes. CCOE/ PESO certified flameproof enclosures are available for hazardous locations.

10.Whether the transmitter enclosure is suitable for corrosive or saline environment?

Yes.

Enclosure Cast Aluminum is epoxy powder coated and is suitable for corrosive or saline environment

Optionally enclosures are available in Stainless Steel (Weather proof or flame proof) or PP material

11.Whether the transmitter is available with integral display?

Yes. Integral LCD display is available with weather proof IP65 and flame-proof enclosure having ATEX, CCOE, IECEx Certification and intrinsic safety option.

Note: It is recommended to use sunshade to protect display and electronics from direct sunlight.

12.What float sizes are available? How to select float and its size?

Float sizes – 41, 75 and 90 dia in SS material; 75 dia in PP and 63 dia in PVDF material.

Float selection is based on-

1. Float material compatibility with service liquid

2. Specific gravity /density of liquid

3. ID of tank nozzle (to ensure suitability of float insertion through the nozzle)

4. Maximum temperature and pressure

Refer float selection table in catalog for detail.

13.What is power supply required for transmitter?

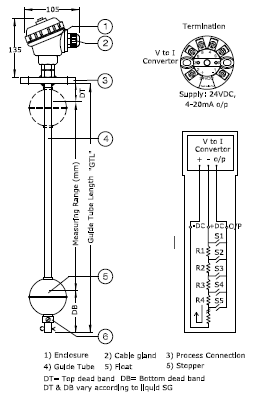

It requires loop powered power supply of 24 VDC.

14.What outputs are available with FGT?

Outputs are available as –

1. 4-20 mA DC (2 wire)

2. 4-20 mA with HART (2 wire)

3. 1 to 5 VDC

4. RTU MODBUS RS-485

5. Wi-Fi enabled with RS485

15.What is the maximum output load?

400 Ohms for 4-20mA output (including 250 Ohms for HART O/P).

16.Whether the output can be configured with PLC/ SCADA or BMS compatible?

Yes..with 4-20mA or RS-485 output.

17.What is the resolution of transmitter?

Transmitter is available with ± 12 mm as standard resolution and ± 6 mm as high resolution.

18.What is a maximum range of the transmitter?

From 500 to 4000 mm

19.What is a dead band of the transmitter?

There is top and bottom dead band (in active area). It varies according float. Refer float selection table in catalog for more details.

20.Whether the transmitter can be calibrated at site or measuring range can be adjusted on site as per requirement?

No. FGT is factory calibrated for given measuring range. FGT with HART output can be set at site for required measuring range

21.What is the maximum temperature and pressure?

Max Temperature: - 40 to 70°C for PP, 100 °C for PVDF and 150 °C for SS material.

Max Test Pressure: Vacuum to 2 kg/cm2 for PP & PVDF, 10 kg/cm2 (SS); 25 kg/cm2 (optional)

22.What information is required to get quotation at earliest?

• Tank Details – tank height/ depth, Nozzle length & its ID.

• Liquid, its nature (corrosive, suspended particles, fuming, viscous) and its specific gravity.

• Upper and lower liquids with Sp. Gr. incase of interface application

• Operating Conditions – max temp & pressure, any agitation in tank or turbulence in liquid

• Area classification- Safe or hazardous

• Accessories (Stillwell or External Chamber) required if any

23.How does float guided transmitter work?

It works on principle of voltage divider network and Archimedes principle. A PCB strip with series resistor chain and reed switch is placed inside the guide tube and convertor module inside the enclosure at top. A float containing magnetic system, follows liquid level and actuate the reed switch and corresponding voltage across the resistor is fed to the convertor. When float position is at bottom of the guide tube, O/P is 4 mA and at top 20 mA. Refer Fig 2. Hence the transmitter provides 4-20 mA o/p corresponding to 0 to 100 % of (measuring range) liquid level in the tank.

24.Can alarms be initiated from the FGT?

No. However it is used in conjunction process indicator controllers like Techtrol Universal Indicator (TUIC) and Techtrol Level Indicator Controller (TLIC), which provide digital display of level with relay output for alarm or control function.

25.Whether the transmitter can be provided with temp sensor?

Yes, It is provided with RTD temp sensor.

26.What approvals & certifications are available for transmitter?

• CE certification

• CCOE /PESO approved Ex-proof enclosures Exd Gr. IIB or IIC T6 for hazardous area applications

• ATEX approval Exd Gr. IIC T6 for hazardous area applications

• Intrinsic Safety

All Rights Reserved © 2021 PUNE TECHTROL PRIVATE LIMITED

Engineered by THE IMPALS