Support

FAQ - Float Pivoted Level Switch (FPS)

It is a single point level switch based on Archimedes principle for partially immersed body and magnetic repulsion.

1.For which applications/ services, FPS is recommended?

It is recommended for free flowing liquids such as water, waste water, slurry, oil, corrosive liquids/ solvent, acids & alkalis.

2.Which wetted part material is available in FPS?

It is available in SS304, SS316, SS316L, PP, PVDF and ECTFE ctd. SS316 material to suit corrosive and non-corrosive services.

3.How one should choose wetted material (MOC)?

It is chosen based on service liquids, operating temperature & pressure. Refer pt. 2 for maximum temperature and pressure.

4.Whether FPS is used for turbulent liquid?

Yes. By using external chamber.

5.Whether FPS can be used for interface level detection?

No.

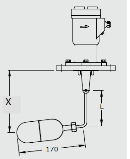

6.Whether the switch can be used for top mounting?

Yes. Specially designed switch with cranked trim can be mounted from tank top for high level detection only. Mention high level switching point (X) from flange bottom. (maximum switching point can be 500 mm from flange)

7.How many set points are achieved in FPS?

It is a single point level switch and generally side mounted on the tank wall. For multiple set points, multiple FPS should be used

8.Whether level is adjustable at site?

No.

9.Whether switch is used for hazardous area applications?

Yes. Float switches with flameproof enclosure Ex d Gr. IIC T6 or ATEX Ex d Gr. IIC T6 are available for hazardous area applications.

10.Whether the switch is intrinsically safe?

No.

11.Whether CCOE/ PESO certified enclosures are available?

Yes. CCOE/ PESO certified flameproof enclosures are available for hazardous area applications.

12.What type of switching element is used in FPS?

It uses micro switches.

13.Whether hermetically sealed micro switches are available?

It is available. Micro switches are hermetically sealed in an enclosure.

14.Whether the FPS requires power supply?

No.

15.How does the FPS work?

It consists of a free moving pivoted float assembly and a switch enclosure. It employs dual magnets, one carried by the float arm and other by the switch carrier housed in the switch enclosure. When the liquid level reaches the operating point of the switch, it brings the like poles of dual magnets opposite to each other and resulting repulsion force ensures a changeover of contacts with snap action of micro-switch

16.What is the output of the FPS?

The output of the switch is potential free micro-switch contacts. It can be SPDT or DPDT as pern requirement.

17.What is micro switch contact rating?

Micro switch contacts are rated for 5A, 250 VAC/ 24 VDC.

18.Whether the switching output can be connected to PLC/DCS or BMS system?

Yes (as o/p contacts are potential free)

19.What is the service life of microswitch?

Mechanical service life of microswitch is min. 10 6 operations

20.What size of floats are available?

Standard - 50 mm dia suitable for nozzle ID of 54 mm

Optional – 60 mm dia

21.What is minimum specific gravity (SG) for which the float is suitable?

Standard float is suitable for liquid SG of 0.8. However float suitable for lower SG upto 0.6 is available on request.

22.How to choose float size of FPS?

Selection of float size depends on inner diameter of nozzle and specific gravity of liquid.

23.What is temp and pressure range for FPS?

|

Material |

PP |

PVDF/ ECTFE ctd SS |

SS |

|

Temperature Range |

-10 to 70 °C |

-10 to 100 °C |

-10 to 150 °C (standard), -10 to 250 °C (optional) -10 to 350 °C with radiating fins ( optional) |

|

Pressure Range |

Vacuum to 3 kg/cm2 |

Vacuum to 10 kg/cm2 upto 25 kg/cm2 (optional) |

|

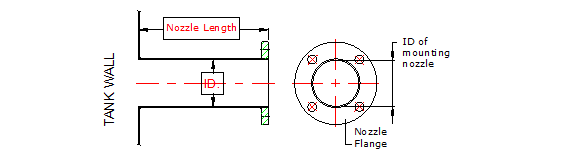

24.What is the total protruding length inside the tank for standard switch?

It is 224 mm standard from switch flange (including nozzle length).

25.What should be the suitable nozzle size for the standard FPS?

Standard FPS with 50 dia is suitable for nozzle ID of 54 mm and nozzle length of 100 mm.

26.What if the nozzle length is more than 100 mm? What is the extended trim option for?

Extended float trim/pivot is provided, where nozzle length of the tank is greater than 100 mm as the float movement may restrict due to extended nozzle. Hence nozzle details (ID & length) has to be provided during enquiry stage.

27.What is switching differential?

It is distance or level between make (switch actuation) and break (switch de-

actuation) of the switch contact. Standard switching differential is 15 ± 5 mm fixed.

Click below link to read blog for detail

https://www.punetechtrol.com/blogs/what-is-meant-by-switching-differential-in-level-switches

28.When external chamber should be used?

External chamber is employed in case-

- There is limited space within the tank or

- Mechanical stirrers cause turbulence or

- Tank needs to be isolated frequently for regular cleaning/servicing

29.What is the use of In situ Test Device?

It is used for checking the operation of switch by moving the float manually with test device without emptying & refilling the tank.

30.When one should select cranked trim option for side mounted FPS?

In slurry applications, standard FPS trim may get break due to accumulation of slurry on it. The cranked trim is already bent is such a way that it prevents accumulation of slurry on it. It is used for high level detection.

31.Where the nozzle should be located to sense lowest level in tank?

Tank nozzle should be located at 150 mm from tank bottom with flange size of 2”

32.Whether the switch can be used for IBR applications?

Yes. For detail refer FPSB catalog.

33.What tests are provided for FPS?

· Hydro pressure test – 1.5 times of working pressure

· Insulation / HVTest

· Performance, Dimensional and visual check

Optional

· Contact resistance

· Contact Rating

· DP (Dye penetrant)

· Helium leak

· IGC (Intergranular Corrosion),

· MTC 3.1 as per EN 10204 3.1

· PMI (Positive Material Identification)

· RT (Radiography Test)

· UT (Ultrasonic Test)

34.What approvals & certifications are available for FPS?

· CE

· IBR

· ATEX or CCOE/PESO Ex d Gr. IIB or IIC for enclosure

· Marine (IRS) are available on request.

35.What precautions are required to be taken while using FPS?

Pl. Ensure-

- Switch material is suitable for liquid, operating temperature and pressure

- Suitability of float for liquid specific gravity

- Liquid should be free flowing and should not contain suspended particles or other strong magnetic material.

- Always use the switch within its max operating limits (temp & pressure)

- Load connected to switch should be less than its contact rating (5A, 250 VAC), else use contactors of higher rating.

- Power supply connected to add and switching supply should be off in hazardous area, before opening the enclosure.

- Ensure arrow (cable gland) on switch enclosure must be pointing downward while mounting the switch on side of the tank

36.What information is required to get quotation at earliest?

· Tank Details : MOC, Nozzle ID and its Length and Process Connection

· Process Details : Liquid and its specific gravity, nature of liquid (clear, viscos, suspended

particles & turbulence) whether agitator is present in the tank.

· Operating Conditions: Operating temperature & pressure.

37.What are the advantages of FPS?

· Compact and reliable switch.

· Rugged construction, do not require electricity

· SPDT or DPDT potential free switch contacts with 5A 250VAC ratings. Switch contacts can be directly connected to PLC/DCS or BMS system

· Easy installation through screwed or flanged connection

· Flame proof enclosure for hazardous area applications

· Very high temperature version upto 350 °C

· External chamber available for turbulent liquids

All Rights Reserved © 2021 PUNE TECHTROL PRIVATE LIMITED

Engineered by THE IMPALS