Support

FAQ - Tubular Level Gauge (TTG)

1.For which applications/ services TTG is used?

It is used for clean liquids such as water, diluted acids /alkalis, brine, solvents, alcohol, diesel, oils (fuel, lube, veg oils).

2.Whether TTG is used for viscous liquids or slurry?

It can be used for free flowing viscous liquids (like oil) with 25 mm dia. gauge glass tube

Not recommended for slurry application.

3.Which wetted part materials are available in TTG?

TTG is available in PP, PVDF, CS, CS ASTM A105, SS304/316/316L and PTFE lined SS304.

4.What is standard glass tube size?

Standard gauge glass tube size is 16 mm OD.

Gauge glass tubes are also available in 19 mm or 25 mmm OD. It is used for viscous liquids such as free flowing oils.

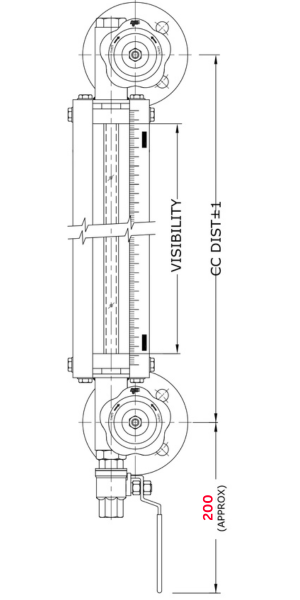

5.What is the CC distance range available in TTG?

300 to 1500 mm

6.What is the visibility of TTG?

Visibility = center to center distance – 150 mm

7.Whether TTG can be used for large tanks?

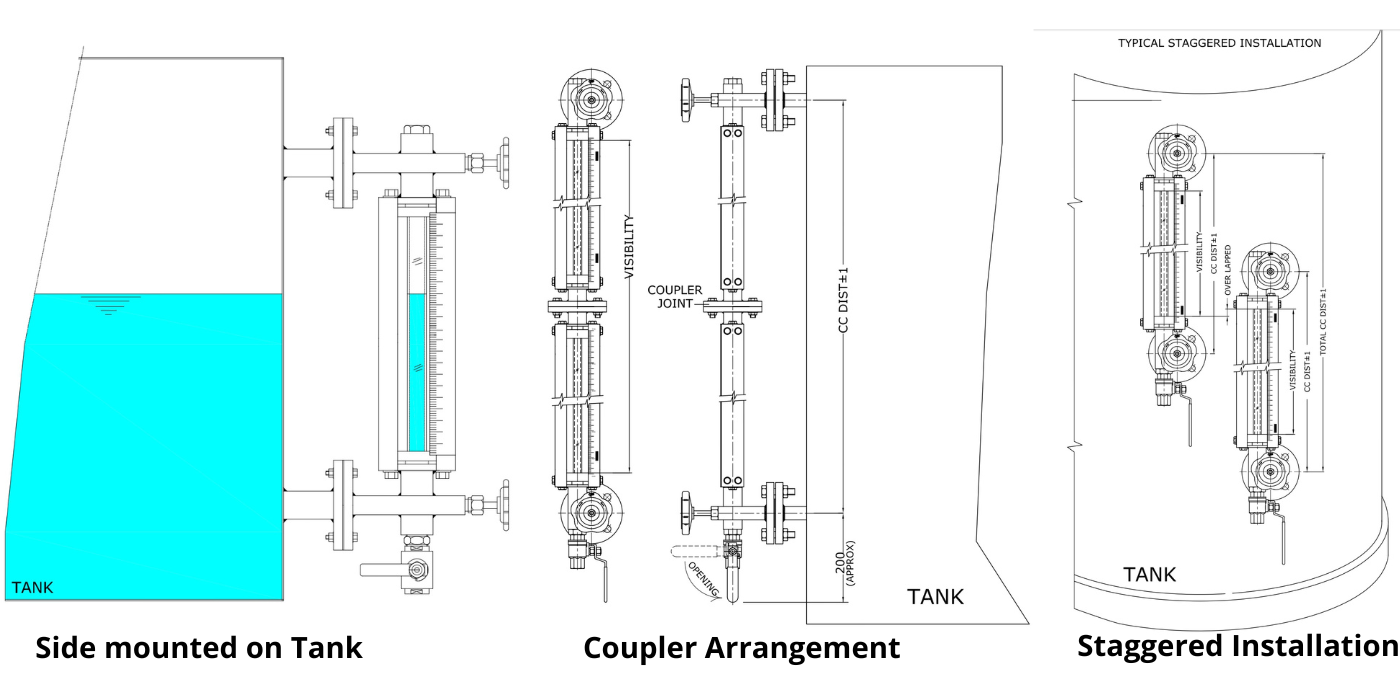

Yes.

For large tanks, multiple TTGs are installed on tank in staggered arrangement.

However, dual TTGs with flanged coupler arrangement can be provided upto 3000 mm.

Necessary support should be provided for the same at site.

8.How much bottom clearance from lower nozzle to ground is required to install TTG on tank?

Clearance required is approximate 200 mm in case valve required at drain.

9.For what temperature and pressure range TTG is suitable?

|

MOC |

Temp Range |

Pressure Range |

|

Metallic (CS, A105, SS304/ 316/ 316L) |

-10 to 200 °C |

Vacuum to 10 kg/cm2 |

|

PP |

-10 to 70 °C |

Vacuum to 3 kg/cm2 |

|

PVDF/ PTFE lining SS |

-10 to 100 °C |

Vacuum to 3 kg/cm2 |

10.What is least count of the scale?

Calibrated scale is available in Polycarbonate with LC of 2 mm and SS304 MOC with LC of 5 mm or 0.5 cm

11.What safety feature is available in TTG? How does it works?

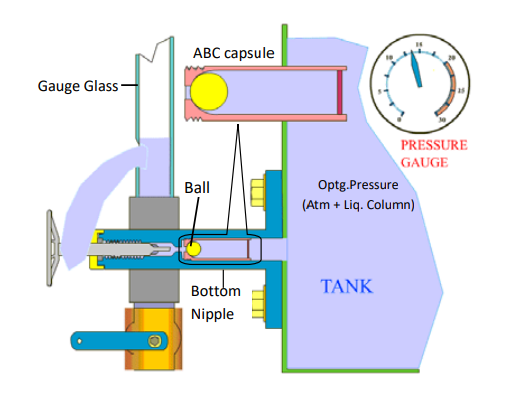

Auto ball check (ABC) facility is provided as safety feature to prevent liquid loss in the event of glass break.

It consists of capsule and freely moving ball along its inner race between stopper and orifice.

It is placed in the nipple of end block at bottom and top side. Refer adjacent figure for placement of ABC in the nipple of bottom side connection.

In case gauge glass breaks, high pressure from vessel side (atm + liquid column) moves the ball to block the orifice and minimize liquid loss from tank.

12.What is the use of integral offset gauge valve and tank isolation valve?

Integral offset gauge valve – It is an integral part of end block used in gauge at top and bottom. It is off center to inlet of gauge to regulate liquid flow coming inside the glass tube. By opening needle valve, liquid in the tank can be observed in glass tube. The offset valve can be closed to stop liquid entering in the glass tube during maintenance in case cleaning of glass or its replacement is required.

Tank isolation valve- It is used between gauge process connection and tank process connection to isolate the level gauge. By closing the tank isolation valve, maintenance activities are carried out or replacement of gauge can be done.

13.What is difference between coupler and staggered arrangement?

Coupler arrangement-

1. Two gauges are connected to each other with coupler flange arrangement.

2. Only two process connections are required.

3. Continuous visibility is not possible as level cannot be seen in the portion, where the gauges are coupled (200 mm aprox.)

4. Necessary support for the gauge should be provided at site.

Staggered Arrangement-

1. Two are more gauges are installed on the tank with overlapping

2. Process connections will be more than two.

No. of process connections = 2 x no of gauges

3. Provides continuous visibility

14.When frost free extension is recommended with TTG ?

It is recommended for low temp liquid applications to prevent frost formation on outer surface of gauge glass for clear visual reading.

15.When Illuminator is recommended in TTG?

It is recommended for installation of gauge in poorly lit area. Illuminator provides uniform light along the glass tube length for clear visual indication.

It consists of Perspex reflector, illuminated through a LED bulb, 80 to 250 VAC with Al. Enclosure IP65 /Ex d Gr. IIB or IIC. The length of single illuminator is 1200 mm max.

16.When Jacketing is recommended in TTG?

It is recommended for liquids, which gets solidify at amb temp. It prevents solidifcation of liquids at amb. temperature. It consists of a SS pipe, which pass through gauge glass with inlet & outlet of ½” NPT (F) at bottom and top end block of gauge. Heating (steam) / cooling agent is passed through this pipe to maintain service material in liquid state.

17.Whether TTG can be used in hazardous area?

Yes.

However, in case of illuminator its enclosure should be ex-proof

18.Whether TTG is used for steam application?

Yes. IBR approved gauge is available.

19.Does TTG is used for interface liquids?

Yes.

20.What information is required to get quotation at earliest?

Tank size, CC distance, process connection, liquid, operating temp & pressure.

21.What are advantages of TTG?

• Direct visual indication of liquid through gauge glass.

• Economical choice for low temp & pressure applications (200°C & 10 kg/cm2)

• No need of power supply

• No maintenance

• Easy to install through flanged or screwed connection

• Available in PP, PVDF & PTFE lined SS material to suit corrosive application

22.How TTG is installed on tank?

It is fitted / bolted to nozzle connection provided on side wall of the tank.

Ensure mounting is in plumb.

Use appropriate gasket between the process connection to prevent leakage.

23.What approvals & certifications are available for TTG?

• CE

• IBR

• CCOE/PESO Exd Gr. IIB or IIC for illuminator enclosure

• IRS (Marine)

• Material certificate 3.1

• NACE

All Rights Reserved © 2021 PUNE TECHTROL PRIVATE LIMITED

Engineered by THE IMPALS