How to find the right level sensor for your application

Introduction:

"There are many applications involving level measurement in process plants. There are various types of level sensors available for this purpose. It is very difficult, to find out the perfect choice. To meet the specific needs of an application, either for liquid or solids in any container, one must take into account the physical/chemical properties of a substance in question.

• How to select right measuring technology

All level measuring instrument is based on certain characteristics of the process material, such as density, pressure, temperature, etc., and its suitability for the same is to be taken into consideration. One can narrow down the options by considering the following factors before selection of right level sensor for level measurement and its suitability.

1) Applications/ Purpose of Level Measurement -

a) Visual Indication:-Various types of Techtrol make level gauges can be used for visual indication only, where the electrical output is not required.

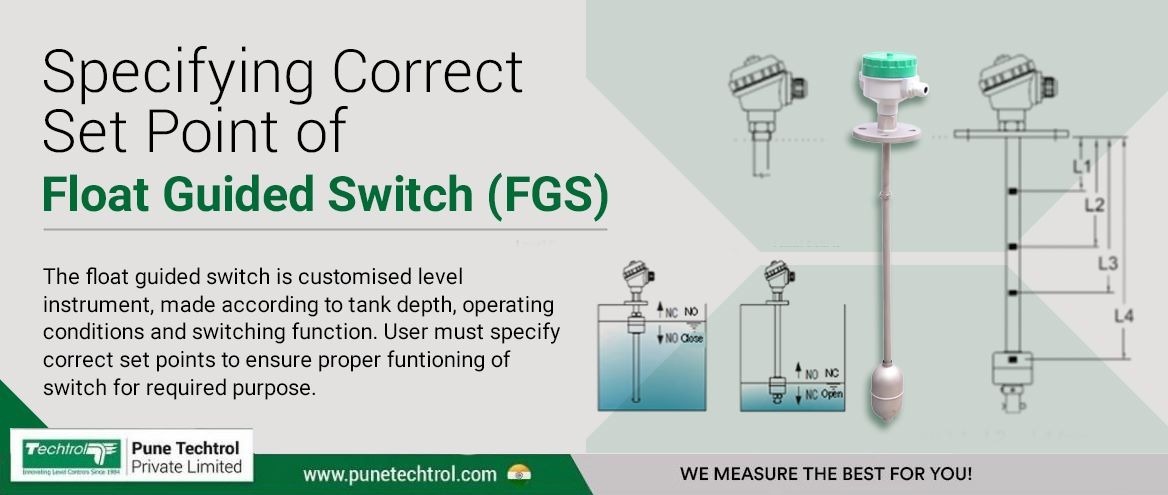

b) Detection of high /low and intermediate level for alarm &control action: - Level switches are useful for detection of the level at a particular point. Techtrol has a wide range of switches available.

c) Continuous level measurement & quantity establishment with remote indication|- Different types of Techtrol make transmitters are suitable for this application. Techtrol makes transmitters are capable of digital communication and can be interfaced to PLC and DCS systems.

Thus Pune Techtrol’s wide range of level measuring instruments includes Level Gauges (visual indication), Level Switches (alarm & control action) and Level transmitters (continuous level measurement).

2) Service Medium whose level is to be measured–

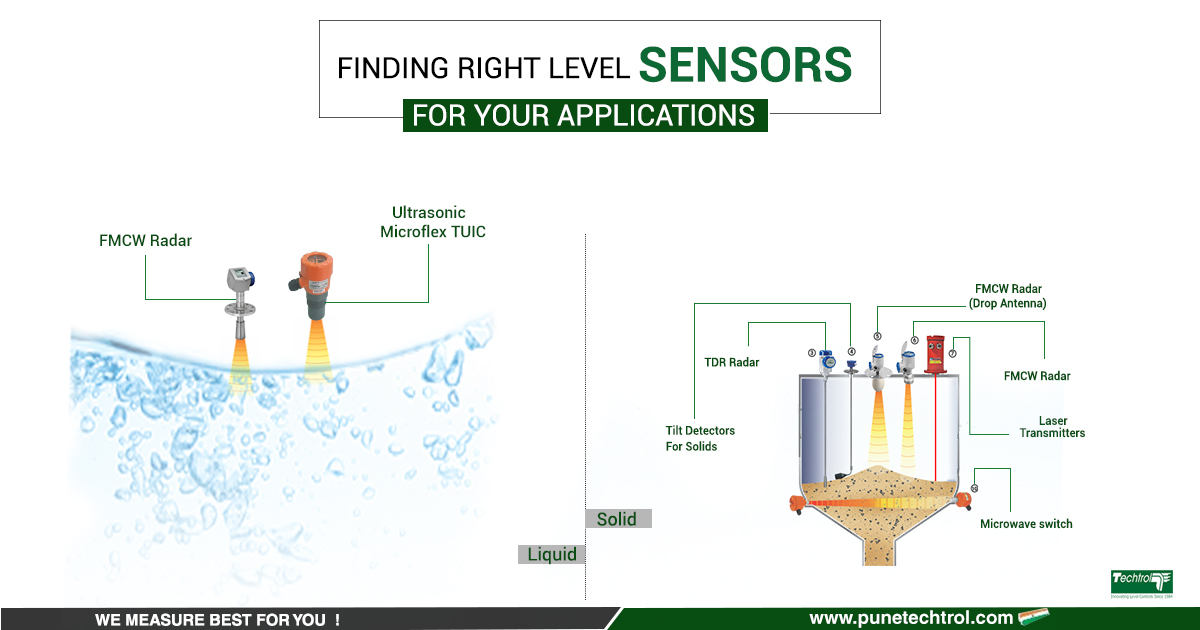

It can be liquid, slurry, interface level of two liquids with different densities or powders/ granules.

Liquids can be corrosive or non-corrosive. Accordingly, the material of construction can be selected. Liquid characteristics such as specific gravity, dielectric constant, viscosity, conductivity must be taken into consideration.

Wide choice of material of wetted parts is available to suit applications. Pune Techtrol’s product range also consists of non-contact type level measuring instruments such as ultrasonic and radar instrument. Level gauges glass type and float type, level switches and transmitters with float/displacer are suitable for clear and corrosive/noncorrosive applications. Air diaphragm-type switch for viscous liquids, capacitance type for low dielectric material and conductivity switch for conductive liquids are available. Capacitance and conductivity based switches are a non-moving type and require little maintenance.

For slurry/ sludge applications, float switches are not suitable as float movement may restrict due to the nature of the liquid. However cable suspended float switches, contact type radar (TDR) and non-contact type ultrasonic and radar are suitable for such application.

Pune Techtrols glass gauges, float type gauges/ switches and transmitters are suitable liquid, liquid interface level measurement.

Powders and granules can be free-flowing or hygroscopic. They pile up to form heap forming a certain angle of repose. Considering these properties, type of switch and mounting position of instruments may be selected. Bulk density and dielectric constant of material should also be taken into consideration simultaneously.

For fuming liquids, gauges are provided with seal pot. Various switches such as float type & displacer type for low specific gravity liquids is available.

3) Operating Conditions-

Minimum and maximum operating temperature & pressure conditions within the tank must be known for the selection of right level sensor for level measurement.

Level gauges and switches for high pressure and temperature applications such as boilers are available.

4) Area of Installation–

Hazardous/ nonhazardous area – electric contacts of switches and transmitter are required to be protected from the hazardous/flammable gases.

Pune Techtrol’s instruments with suitable flameproof enclosures or intrinsically safe arrangement are provided according to area classification

5) Mounting Orientation-

Depending on mounting position available on the tank i.e top, side, bottom mounting level instruments are available

6) The desired Accuracy –

Certain processes require accurate level measurement and control.

Our Ultrasonic, Radar transmitters provide an accurate level measurement for liquid, slurry and powder applications

How these are helping the customers

By virtue of its wide range of level measuring and control instruments, Pune Techtrol is able to meet the varied requirements of the customer for numerous specific applications. Techtrol’s application engineers study the process parameters and suggest appropriate instruments to suit the applications. Due to our stringent quality control measures, Techtrol instruments are highly accurate and reliable. After sales support and availability of spare parts are always ensured to cater to the needs of the customer.

Nowadays most of the processes are controlled digitally from the central control room. Digital communication capability of Teachtrol instruments can help ready interfacing. Additionally, these instruments can be integrated with IOT applications.

Conclusion

There is no universal technique for selection of level measuring instrument which is suitable for all services /applications. Detailed study of various parameters, application, and interaction with the customer can help to select the correct level sensor for every application.