Specifying Correct Set Point of Float Guided Switch (FGS)

Float guided switch is a tailor made level instrument. It is manufactured according to tank depth considering liquid and its specific gravity, operating temperature & pressure, number set points and switching function required at set point i.e. close contact or open contact. Its switching set points are factory set and it is ready to install. Hence, it is mandatory to specify the set points by the user prior to manufacturing.

The set points should be specified in correct way. Misunderstanding regarding the set points may lead to improper functioning of level switch and will not be suitable for required purpose.

In Techtrol Float Guided Level Switch, two types of reed sensors are used.

- SPST [Normally Open (NO)] Type - Reed sensor contacts are open in absence of magnetic field. It actuates to close the contact in magnetic field of float.

- SPDT [1 Change Over (1C/O)] Type – In this, reed sensor has three contacts Pole (common), Normally Open (NO) and Normally Closed (NC). In the presence of magnetic field, reed sensor actuates and NC contact gets open and NO contact gets closed.

Let’s understand correct way of specifying the set points. While mentioning the set points, below points should be considered.

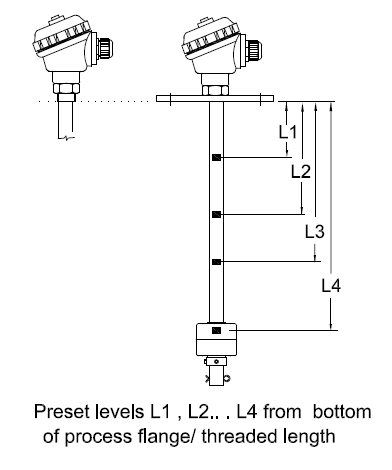

1.Reference of the preset point –

Set points are measured with some reference point.

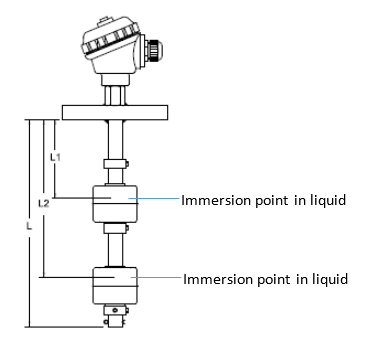

For Techtrol Level Switches, all the set points are measured from the reference of bottom of the process flange or threaded connection or triclover ferrule as shown in figure below.

Always mention the set points with reference to process connection as stated above.

2.Switching function at preset point during level rising or falling –

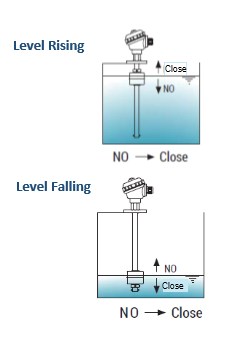

Switching contact function at set point can be open contact or close contact. It is mandatory to specify this information in case of ‘NO’ type reed sensors.

The set points are set for required contact function considering level rising or level falling condition.

SPST (NO) Switch

- Switch Function: NO to Close contact during liquid Level Rising.

- Reed contact closes as liquid level rises at preset point.

- Reed contact opens as liquid level falls below preset point

- Switch Function: NO to Close contact during liquid Level Falling.

- Reed contact closes as liquid level falls and reaches at preset point

- Reed contacts opens as liquid level rises above preset point.

Similarly, NC to Open contact on level rising or falling can be given.

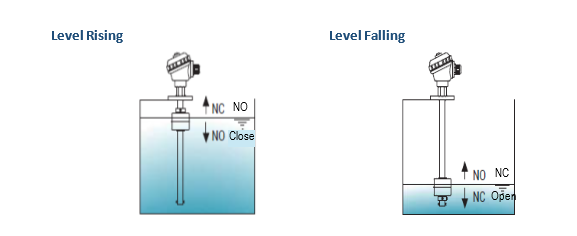

SPDT (1 C/O) Switch

Switch Function: Contact NO - P - NC to NC – P - NO is set on Level Rising of Level Falling as required.

If level rising and falling condition is not considered, set points deviate with few mm.

Preset points of the level switch are set at float immersion level in a particular liquid.

Preset point L1 & L2 are set at immersion point w.r.t flange in below figure

Important Note

Float immersion in liquid depends on specific gravity of the liquid. Lower the specific gravity, more the float immersion in liquid. Accordingly, possibility of lower set point (L2 in above figure) near the guide tube bottom may vary.

To get right level switch for required application, please fulfill following details at the time of enquiry.

- Liquid and its specific gravity.

- Tank depth, its nozzle height & ID and process connection available on tank.

- Number of set points from bottom of flange/threaded connection.

- Switching function (open or close contact) during rising or falling.