Level Measuring Instruments and their Types

In any process industry, parameters such as level, pressure, temperature, flow, pH, conductivity, density etc. have to be measured and controlled to get desired end product in terms of quality & quantity and also for efficient operation of the process.

What is Level?

It is the height or depth of liquid or solid content above a reference point, specific to particular vessel.

Significance of Level Measurement

- Control and monitoring of process parameters – to automate various operations e.g. to start/ stopmotor manually or automatically. Actual level of liquid /solid can be monitored locally or remotely. In case of certain processes maintaining level at a particular point, continuously is extremely important

e.g. Water level in boiler drum is required to be monitored and controlled accurately as excess of water level result in carryover of water into steam whereas lower water level will damage the boiler due to starvation & exposure of furnace to overheating.

Level of liquids/solids can be monitored remotely anywhere, anytime using

IIoT gateway. By this way it can serve as a vital management tool.

- Inventory control and monitoring – of high value material. It is essential to maintain optimum inventory so as to run the production process smoothly. By measuring level, inventory can be monitored in terms of weight and volume. It also helps to control loss or leakage of material and its proper accounting thereby.

- Custody Transfer – Accurate level measurement is required during transfer of costly material such as raw or refined petroleum products between ships, main storage tanks, road tankers and other similar transactions. Volume of actual liquid is calculated precisely by measuring level.

- Safety – Some hazardous chemicals like acid/alkali can be harmful to persons working with them.Accurate level measurement and control prevents overflow condition and helps avoid spillage of hazardous/corrosive material since it can be harmful to personnel working there. Prevention of spillage also averts environmental safety issues resulting in financial losses.

- Level detection is used to prevent dry run condition of pumps thereby protecting pump & motor ensuring safe operation.

Types of Level Measuring Instruments

Level Measurement Techniques-different types of level measuring instruments are available in market based on various principles of physics such as Archimedes principle, communicating with vessels (liquid finds its own level), refraction of light, magnetism, conductivity, capacitance, piezo electric effect (vibration), air pressure, hydrostatic pressure, ultrasonic and radar.

Selection criteria for appropriate instrument is based on

- Purpose of level measurement such as

- Visual indication only

- On/off control (manual/automated)

- Remote indication, monitoring & control

- Type of liquid/solid and its characteristics

- Operating conditions i.e. temperature & pressure

- Accuracy requirements

- Mounting arrangement

Level instruments are available in various material such as CS, SS304/316/316L, Monel, Inco alloy, Hastalloy, Titanium, PP, PVDF, PTFE or ECTFE coated SS to suit liquid and operating conditions.

Broadly level instruments are classified as

Level Gauges for Liquids

Level Switches for Liquids & Solids

Level Transmitters for Liquids & Solids

1) Level Gauge -

It is a mechanical device used to provide direct indication of liquid level in tank and does not require electric supply for its operation.

Level gauge is used only for visual indication of liquid level in tank. However, level gauges using float are provided with switch and transmitter facility, which can be used for control and remote indication.

Level gauges based on the principle that ‘liquid finds its own level' by communicating with vessels/containers are direct reading type gauges. It makes use of transparent glass tube or flat glass and liquid level is observed through the glass.

a. Glass Type Level Gauges - Direct reading type

- Oil Level Gauge- ‘OLG’

- Mini tubular Level Gauge –‘MTTG’

- Tubular Level Gauge –‘TTG’

- Reflex Flat Glass (Armoured) Level Gauge –‘RFG’

- Transparent Flat Glass (Armoured) Level Gauge -‘TFG’

- Bicolor Multiport Level Gauge- ‘TBLG’

Float type level gauges are based on Archimedes principle and liquid level is observed on the scale by means of a pointer.

b. Float Type Level Gauges

- Float & Board Level Gauge- ‘FBG’

- Float & Dial Gauge –‘FDG’

- Magnetic Float and Dial Gauge –‘MFDG’

- Float & Tape Gauge – ‘FTG’

- Magnetic (Bypass) Level Gauge –‘MLG’

2) Level Switch -

It is an electro-mechanical instrument. It is available as single point or Multi point level switch and is used to detect liquid level at particular point.

It uses reed switch, micro-switch or relay as a switching element.It can be mounted at high, low or intermediate level of the tank.As the level reaches at particular point, corresponding switch actuates, which provides potential free i.e. normally open (NO) or normally closed (NC) switching contacts as an output. However, some switches provide potential enabled contacts i.e. PNP or NPN output.

Its output is used for indication, alarm generation or to control or automate (on- off operation) auxiliary devices like motor/ pump or solenoid valve. The output can be directly connected PLC for further control operation.

‘Techtrol Level Controller (TLC) – TLC' is provided alongwith with level switch for various switching functions (e.g. pump control) or to enhance output power of low powered switches.

Level switches are based on various principle- Archimedes, magnetism, conductivity, capacitance, vibration and air pressure.

a. Techtrol Level Switches for Liquids

- Miniature Float Guided Switch –‘MFGS’

- Miniature Float Pivoted Switch –‘MFPS’

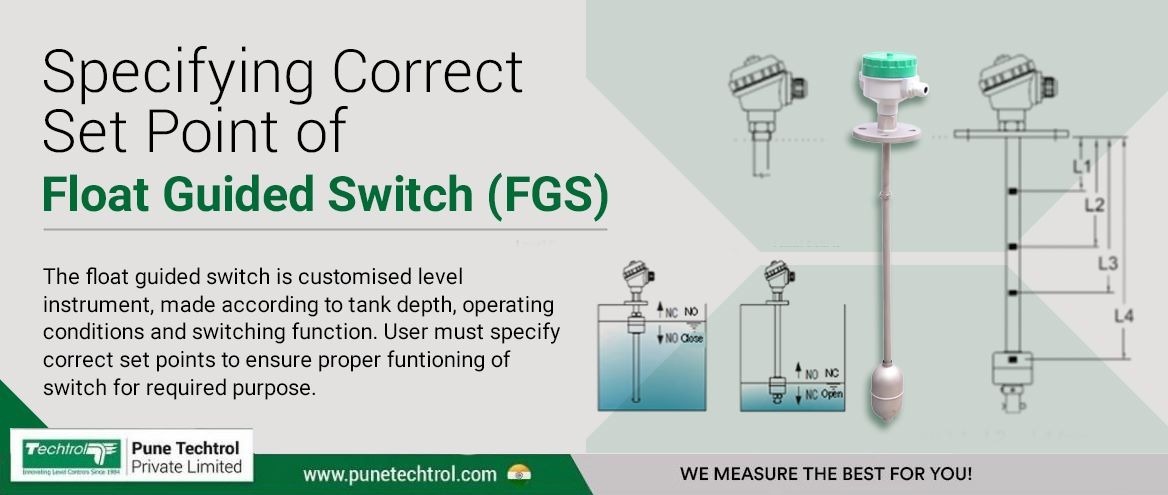

- Float Pivoted Level Switch –‘FGS’

- Float Guided Level Switch – ‘FPS’

- Float Operated Tilt Level Switch- ‘FTS’

- Conductivity Level Switch – ‘CNS’

- Capacitance Level Switch –‘CPS’

- Displacer Level Switch – ‘DS’

- Vertical Level Control Switch- ‘VLC’

- Chamber Float Switch – ‘CFS’

- Air Operated Diaphragm Switch –‘ADS’

- Vibrating Fork Switchfor Liquids -‘VFSL’

b. Techtrol Level Switches for Solids

- Rotary Paddle Level Switch– ‘RPLS’

- Vibrating Fork Switchfor Solids – ‘VFSS’

- Vibrating Rod Switch –‘VRS’

- Vibrating Diamond Blade

- RF Admittance Switch – ‘RFA’

3) Level Transmitter –

It is a continuous level measuring instrument. It provides continuous output of analog signal, proportional to liquid level (0 to 100 % of measuring range) in tank.

It is used for continuous level indication of material, locally or remotely for monitoring or control action. Its output is also used to calculate volume of the material in the tank.

Transmitter output is available as 4-20 mA,1 to 5 VDC or 4-20mA with HART communication or RS-485 Modbus RTU protocol.

The output of the transmitter can be transmitted through wire over a distance and can be connected to indicators for remote indication or to PLC/ DCS/ SCADA for indication and control action.

Transmitters are available as ‘Contact Type’ and ‘Non-contact Type’ for liquids and Solids.

A contact type transmitter comes in direct contact with material. It is based on Archimedes principle of floating (float) body, submerged body (displacer), capacitance and hydrostatic pressure.

A non-contact type transmitters does not come in contact with material. It is based on ultrasonic or radar principles.

a. Techtrol Level Transmitter for Liquids, Contact Type

- Float Guided Level Transmitter – ‘FGT’

- Capacitance Level Transmitter – ‘CPT’

- Capacitance Level Transmitter for Fuel – ‘CFT’

- Hydrostatic Level Transmitter –‘HLT’

- Displacer Torque Tube Level Transmitter – ‘DTT’

- Guided Wave Radar Transmitter- ‘G-TROL'

- Magnetostrictive Level Transmitter – ‘MLT’

b. Techtrol Level Transmitter for Liquids, Non-contact Type

- Ultrasonic Level Transmitter – ‘Ultratrol’

- Radar Transmitter – ‘INTROL’

c. Techtrol Level Transmitter for Solids, Contact Type

- Guided Wave Radar Transmitter - ‘G-TROL’

- TDR Radar Transmitter – ‘VF04’

d. Techtrol Level Transmitter for Solids, Contact Type

- Radar Transmitter –‘INTROL’

- FMCW Radar Transmitter – ‘RD’, ‘RX’, ‘RA’ series