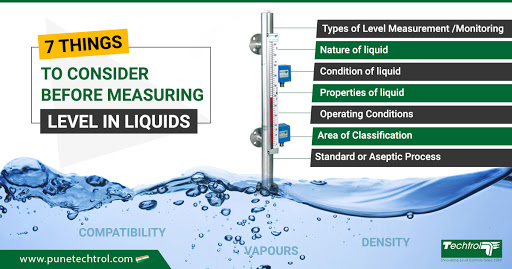

SEVEN THINGS TO CONSIDER BEFORE MEASURING LEVEL OF LIQUIDS

Complex automated systems are in-demand. The requirement for ever-more-stringent process control, and an inexorably strict condition of regulating the process, drive the engineers to seek more precise level measurement & control systems forliquids. Enhanced accuracy of level measurement makes it conceivable to decrease complex process fluctuation, bringing about high-quality results, lesscosts, and much lesser waste.

For measuring the level of liquids–heavy or light-weight, there are certain characteristics that need to be considered. Though liquids have more predictable characteristics than solids, the damage caused by the improper selection of instruments can be of the same intensity.

In this article, we shall discuss some key factors that you should take into consideration before you decide measuring levels in liquids.

- Types of level measurement /monitoring

There are various kinds of monitoring methods that one needs to understand before selecting the right tool for level measurement.

- There are gauges in the collection that helps in the visual indication of the level.

- The detection and control of the level can be very well be achieved with the help of different types of switches. Switches are versatile, reliable, and robust in their function. The easy-to-install switches come in various sizes and make.

- Transmitters on the other hand are useful for the continuous monitoring of the level in the tanks. The process application and functional requirement you choose, decide the type of instrument required.There are range of transmitters that offer high temperature and pressure operations suitable for remote programming as well.

- Nature of liquid:Liquids can cause corrosion. Some liquids are highly corrosive. The liquids in the automation processes can be clean and clear, or may have suspended particles. They can even be corrosive, non-corrosive, hazardous, acids, alkalis, solvents, orexpensive liquids, depending on their properties and uses. Hence compatibility of the material of construction of the level measuring system must be studied prior to dealing in liquids.

Properties of the liquidneed to be pointed out to the engineers from whom you are planning to buy the level measuring instruments, because it aids them to select appropriate instrument.

- Condition of liquid:Condition means the activity of the liquidwhen in the tank. They can be foaming, fuming, boiling or turbulent in nature.Depending on the activity of the liquid, the required accessories to reduce the effect ofagitation of liquid on the instrument can be chosen. Formations of vapours is a feature associated with most of the chemicals (especially, solvents & fuels). Vapours can disrupt the functioning of sensors, build pressure, and in turn result into incorrect readings. There is need to vent the tanks well before considering to install a level measuring unit.

- Properties of liquid:Properties in liquids such as density (Kg/m3), viscosity (CPS), conductivity (uS) or dielectric constant needs to be studied and analysed before deciding on the equipment.These properties are responsible for the proper functioning and accuracy of the equipment. The variations in temperature can cause changes in densities. Hence it is an important factor to be considered while selecting the instrument. The measurement of levels in liquids becomes even a further challenge when the density affects the pressure.

- Operating conditions:Temperature and pressure conditions to which the liquids are subjected must be noted. Level measuring instruments have a minimum and a maximum limits for these parameters.Considering these limits helps to select the equipmentwhich will withstand them.

- Area classification: As per the statutory norms and industry standards the area (hazardous , non-hazardous) within which the equipment and machinery are set up, requires to be informed to the instrument manufacturers. The environment where the liquids are handled can behazardous, non-hazardous or dusty. Studying this part can help to choose the instrument enclosure with appropriate protection of weather proof (IP)/flameproof that can function seamlesslyin the respective environments.

- Sterile/Aseptic process:Biotech and pharmaceutical processes have to be carried out under sterile condition. These processes require special type of process connections like triclover fittings to reduce chances of contamination. Hence contact parts must have mirror finish. Non contact type instruments such as ultrasonic and radar level transmitters are preferred for such applications. Also these processes involve high temperature and pressure conditions. Ultrasonic, guided-wave radar are among one of the more versatile technologies available.

If all of the aforementioned six factors are considered for level measurements in liquids, then you are good to go out to choose the proficient equipment that can cater to your requirements in diverse processes.