Variants of Level Gauges and Their Construction or Working

Conservation of any liquid including water can be done only by precise monitoring of its level. Water is the simplest and most indispensable liquid fundamental to human existence.

We use it extravagantly in our day to day lives, but do we actually worry about the amount of water we need for the particular the purpose? Such unnecessary waste of water creates scarcity and also has bad effect on our environment. Monitoring water level, and thereby its consumption, can help in its conservation.

The estimation of quantity of liquid and its consumption/conservation can be monitored using level gauges. Pune Techtrol, a prominent level gauges manufacturers in India, showcases a wide range of level gauges for liquids, which will make your liquid level measurement easy and meaningful!

Features of Level Gauges

- Completely mechanical device

- Doesn’t require power to operate

- Mostly used for visual level indication

1. Glass Type Level Gauges

a. Tubular Level Gauge (TTG)

TTG is simple, low cost & reliable gauge for direct reading of liquid level in tank.

Operating Principle- Liquid seeks its own level

Working -

Tabular Level Gauge for liquids consists of glass tube fitted between two end blocks. The guard, ‘C’ channel or tie rod is provided to protect gauge glass & prevent it from accidental blows.

The gauge is mounted parallel to the side of the tank to form close loop causing the liquid it level in the gauge. Thus liquid level can be observed through a gauge glass.

It is available in the material of CS, SS304/316, PVDF, PTFE lined SS304 and suitable for maximum temperature of 200°C and pressure of 10 Kg/cm².

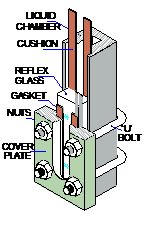

b. Reflex / Transparent Flat Glass Level Gauge (RFG & TFG)

Reflex gauge is designed for distinct visual indication of liquid level in vessels under high temperature and pressure. It is suitable for clean and colorless liquids.

Operating Principle - Communicating vessels, reflection and refraction of light.

Working -

It consists of liquid chamber and flat glass whose inner surface has precisely molded prismatic grooves cut on it. Hence it is called “Reflex flat glass”.

The inner surface is of the flat glass is placed on liquid chamber with cushion & gasket and cover plate and all held together by U bolts as shown in adjacent figure. The chamber is fitted with end blocks at its top & bottom.

The gauge is mounted parallel to the side of the tank. The portion of the gauge-glass, up to which the liquid level stands, appears black due to refraction of light passing through liquid and the prismatic grooves, whereas it appears to be silvery-white in the glass portion above liquid level or that covering vapor space.

Thus RFG eliminates all the possible errors that occur while measuring liquid level. This level gauges for liquids are available for pressure and temperature rating of 210 Kg/cm² & 400°C respectively.

c. Transparent gauge:

The construction is similar to that of reflex gauge except that it consists of a liquid chamber formed by one metal piece and a pair of gauge glasses that have smooth finish on both sides and are fitted on front and rear side of liquid chamber. It is used for dirty and viscous liquids and liquid/ liquid interface .They are available for pressure and temperature rating of 210 Kg/cm² & 400°C respectively.

2. Float Type Level Gauges

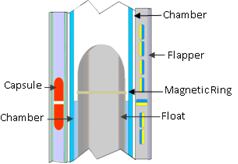

a) Magnetic Level Gauge (MLG)

Pune Techtrol’s Magnetic Level Gauges are designed for visual level indication of liquids which attack glass or are hazardous. The rugged glandless, non-contact type construction provides safety while dealing with toxic and highly corrosive liquids.

Operating Principles – Communicating vessels, Archimedes principle & Magnetic attraction

Working -It consist of a magnetic float housed inside the chamber whose Material Of Construction (MOC) is suitable for the liquid of which level is to be measured, and level indicator clamped externally on the chamber. The float follows liquid level and is magnetically coupled with indicator.

The indication of level can be displayed in three types

- Red Magnetic Follower Capsule- is simple and economic design. It moves within the glass tube, filled with water (to reduce friction) according to float movement and liquid level can be read against a scale.

- Bi-color Flappers – The flappers are white on the front and red on the reverse. They are embedded with permanent magnets which couple with float magnet and ensure interlocking with adjacent flappers, to eliminate random rotation of flappers. The flappers rotate according to float movement and change its color from white to red when float rises on liquid level and vice-versa when it falls. The liquid level is represented with red bar column on indicator and read on the scale. The MOC is available in plastic and SS which is suitable for 150°C & 250°C respectively.

- Bicolor Rollers – Construction and working is similar to flapper. But the MOC is available in plastic and ceramic which is suitable for 150°C & 400°C respectively.

It can be provided with alarm switches and transmitter which can be clamped on the chamber externally.

b) Float and Board Gauge (FBG)

FBG is simple &economical gauge used for liquid level indication of bulk storage tanks under atmospheric pressure.

Operating Principle- Counter weight balancing method and Archimedes principle.

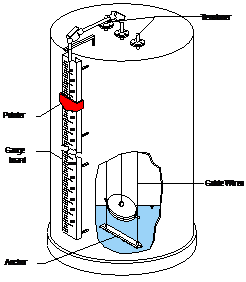

Working – It consists of float connected to wire rope via set of pulleys. Float follows liquid level and pointer glides over gauge board, fitted outside the tank, to indicate liquid level.Pointer is in Top position when tank is empty and in bottom position when Full.

It can be provided with guide wire to prevent horizontal movement of float in the tank. It can be provided with seal pot to prevent venting of liquid fumes. Provision of alarm switches is also possible.

The gauge is available in material of PP, SS304/316, and PVDF ctd. SS304 and is suitable for maximum temperature up to 150°C and atmospheric pressure.

C) Float & Tape Gauge (FTG)

FTG is reliable and accurate level gauge for continuous level indication of almost all service mediums and tank types. Commonly used for custody transfer of liquids. (Inventory management).

Principle – Counter weight balancing method and Archimedes principle

Working – It comprises of float attached to a SS tape whose other end is wound on storage drum through a sprocket pulley carrying constant torque spring housed inside the enclosure and gear mechanism for pointer movement.

Float follows the liquid level and ss tape gets wound and unwound on sprocket pulley whose rotation is transferred to a pointer through gear mechanism to indicate accurate liquid level on dial.

FTG is available in material of SS316 and can be provided with guide wire to prevent horizontal movement of float in the tank. It is suitable for max temperature of 120°C and atmospheric pressure.

d) Float & Dial Gauge (FDG)

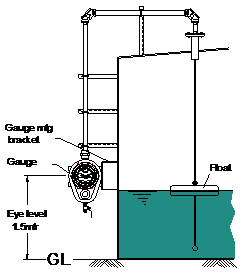

FTG is reliable and maintenance free gauge suitable for liquids in underground and partially underground tanks.

Principle - Counter weight balancing method and Archimedes principle

It is available in analog and digital indication. It consists of float attached to SS wire rope, the other end of which is wound on drum carrying constant torque spring housed in weather proof enclosure. Float rises and falls according to liquid level and results in rotation of drum.

Its motion is transferred to pointer through a gear mechanism and level is indicated on dial. In case of digital indication motion of gear induces variable voltage which is converted into 4-20 mA signal output and level is simultaneously displayed locally on seven segment LED display.

Techtrol is a leading level gauges manufacturers in India provides FDG in material of SS04/316 or PVDF ctd SS and is suitable for max temp of 100°C and atmospheric pressure. FDG with analog indication is available with two alarm switches.