Volume Measurement Using Level Sensor & Strap Table

Expensive liquids such as crude oil, gasoline, diesel, petrochemicals, solvents and several other chemicals are required to be measured in terms of volume for their proper inventory control and custody transfer. Volume measurement helps to minimize loss and achieve cost savings.

In case of large diameterstorage tanks, small increment in level corresponds to large volume of liquid. Volume calculation for cylindrical tank can be done easily with the formula.However, for irregular tank shapes such as spherical tanks or horizontal cylindrical tanks, volume calculation is complex.

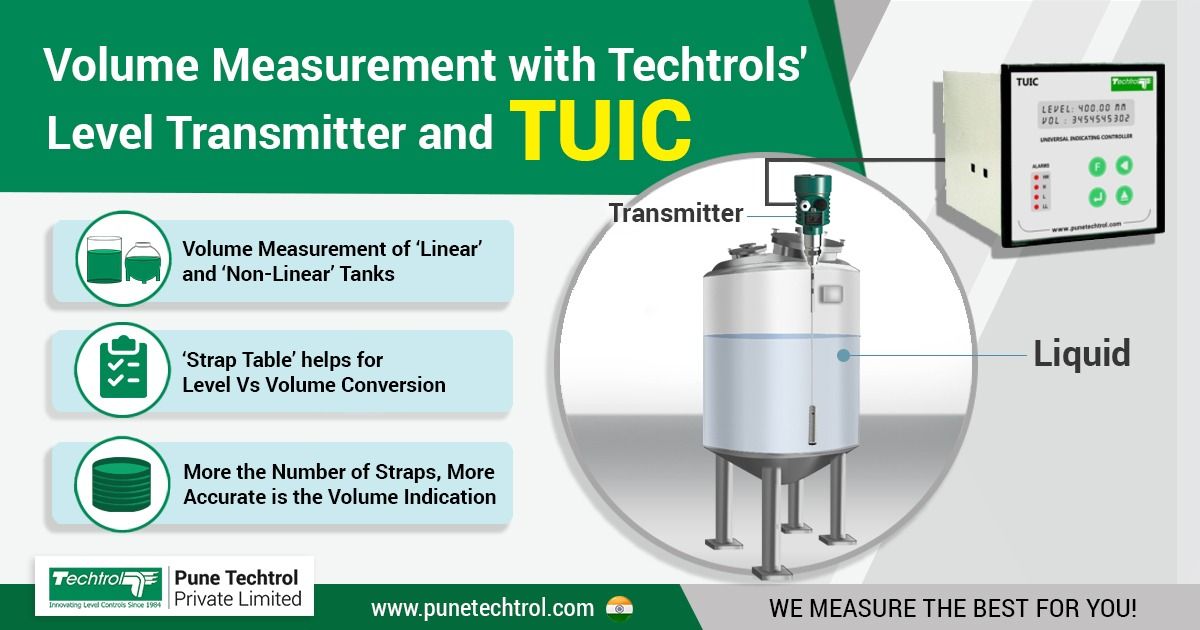

Hence, strap table is used to calculate volume of liquid in a tank from linear measurement of liquid level. This table is also called as tank calibration chart, tank gauge chart, calibration table or dip chart. The strap table consists of two columns showing level and corresponding volume of liquid at various levels of the tank.Here, tank height is divided into number of straps for known equal level or height and volume against each strap is mentioned in the table.Often, level ismeasured in inches, mm, cm or % and volume is mentioned in m3, KL, gallon or tons. Strap table can be generated for linear as well as non-linear tank. Within each strap, volume calculation is linearly interpolated with level. Hence,more the number of straps, more accurate is the volume indication.

In the old days, one had to carry and refer to the strap table to check volume of liquid. With advancement in technology, the controller or sensor are fed with data of strap table and it automatically provides indication of volume with reference to the level.

If the strap table is not available, the experts at Pune Techtrol will help you to generate strap table from the tank dimensions and shape.

Techtrols’ Universal Indicator Controller ‘TUIC’is based on microcontroller to provide level as well as volume indication alongwith tank number. This may be used in conjunction with any level transmitter. The display indicates 5 digit level in mm, cm, m or % and 10 digit volume in m3, KL, gal, tons or %. It uses strap table forvolume calculation of linear and non-lineartanks. Number of straps and its corresponding volume is required to be entered,initially, through keypad. It has four relay outputs and optionally provided with 4-20mA retransmission of RS-485 communication for remote indication and control action.

Accurate calculation of volume requires accurate measurement of liquid level.

Pune Techtrol has wide choice of level transmitters like Float Guided Transmitter(FGT), Capacitance Type Transmitter (CPT), Hydrostatic Level Transmitter (HLT), Guided Wave radar Transmitter(G-TROL), Non-Contact type Ultrasonic and Radar Transmitter (Ultratrol & INTROL) and Magnetostrictive Transmitter (MLT) for high accuracy. These transmitters continuously measure liquid level in the tank and provide 4-20 mA output. This o/p is connected to TUIC. Once the strap table is entered in controller, it shows the volume indication as the liquid level in tank rises or falls.

We also carry out tank calibration activity for new as well as tanks in service and tanks of various shapes & sizes.We make sure that the highest degree of measurement accuracy is guaranteed. Our experienced and qualified engineers are equipped with state-of-the-art measuring devices such as laser based instruments and precise linear measuring instruments for tank calibration. Additionally, we also provide investigations/ estimation of loss and remedial measures from experts with years of industry experience.